|

|

2010 SMUHA Galley Building

Many, many hours of work went into making what was a particularly bonny galley Skiðblaðnir. The 2010 galley design has an

interesting history. Shortly after David was elected Jarl, he was chatting to an old friend when the question of galley

construction was raised. It was explained that he had a concept for efficiently making elegant galleys using software

generated plank patterns. After a presentation of the flat-pack galley idea to the rest of the committee it was decided to give

this new approach a go. Work started in early May – just to make sure there was sufficient time to have another go, if needed!

The main interesting aspects of the whole procedure were the high-tech design/construction

methods, and the decision to make her a complete sea-worthy hull rather than platform

based. The idea was to use sophisticated technology where appropriate, to supplement the

traditional craftsmanship. This allowed fair lines to be achieved, without excessively

time-consuming amounts of fitting.

The design specification was that she had to be able to float with a large number of torches aboard, yet not burn through too quickly. Overall dimensions (7m over her stems, 2m beam) were limited by the locations and roads she would need to be pulled through. Within those limits the hull shape was designed to be relatively full-figured with a flat bottom, yet elegantly proportioned with expressive curves.

The hull shape was created using purpose written 3D CAD software. This provided the 2D pattern shapes for the planks, including the required seam overlap offsets. Each full plank was completely assembled prior to being attached to the hull.

The design specification was that she had to be able to float with a large number of torches aboard, yet not burn through too quickly. Overall dimensions (7m over her stems, 2m beam) were limited by the locations and roads she would need to be pulled through. Within those limits the hull shape was designed to be relatively full-figured with a flat bottom, yet elegantly proportioned with expressive curves.

The hull shape was created using purpose written 3D CAD software. This provided the 2D pattern shapes for the planks, including the required seam overlap offsets. Each full plank was completely assembled prior to being attached to the hull.

The issue of avoiding early burn-through was solved by the use of a multiple skin approach. The outer planked skin was made

from lightweight 4mm ply. This, being very flexible, permitted simple assembly and adjustment of overall shape by squeezing

and pulling the combined shell. Once the hull was fair, the seams were sealed with GRP, producing a strong and resilient

shell similar to the "stitch and tape" technique used for Mirror dinghy construction. Transverse frames were then attached to

this shell for stiffening, and then an inner skin of two layers of much thicker sheeting was attached to the frames. This

provided considerable resistance to burn-through in the locally critical zones, without adding weight higher up.

In order to simulate the visual effect of thick clinker plank

landings, each of the 4mm outer planks were edged with

strips of wood prior to assembly.

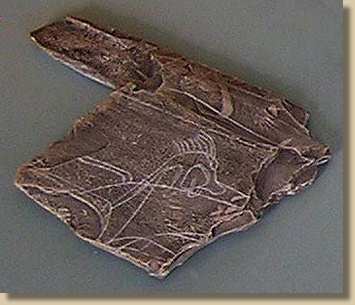

The head and tail were hand carved from rigid polyurethane foam slabs, covered with papier mache, painted gold, and finally "aged" with fake dirt. The head was equipped with "ruby" jeweled eyes. Two sets were necessary. During the day the eyes used had conventional mirrored backing mounts. For the procession and burning these were exchanged for identical jewels with back illumination. Illuminated galley eyes were first introduced in the Lerwick Up Helly Aa in the early 1900's, but were discontinued soon after. The design of the galley head was based on the well-known dragonhead stone carving found at Jarlshof. This is especially appropriate as the galley construction was carried out across the water from the site at the Ness Boating Club who very kindly allowed SMUHA the use of the shed for the construction.

The head and tail were hand carved from rigid polyurethane foam slabs, covered with papier mache, painted gold, and finally "aged" with fake dirt. The head was equipped with "ruby" jeweled eyes. Two sets were necessary. During the day the eyes used had conventional mirrored backing mounts. For the procession and burning these were exchanged for identical jewels with back illumination. Illuminated galley eyes were first introduced in the Lerwick Up Helly Aa in the early 1900's, but were discontinued soon after. The design of the galley head was based on the well-known dragonhead stone carving found at Jarlshof. This is especially appropriate as the galley construction was carried out across the water from the site at the Ness Boating Club who very kindly allowed SMUHA the use of the shed for the construction.

2010 Galley builders & painters

Rear row - left to right: Robert Halcrow, Brian Halcrow, Scott Lobban, David Smith (Jarl), Kevin Adamson, Brydon Robertson, Dale Smith, Erik Moncrieff (in box top right).

Front row - left to right: Ross Smith, Ian Jarmson, Bobby Halcrow, Alma Stove, Leonard Christie.

Rear row - left to right: Robert Halcrow, Brian Halcrow, Scott Lobban, David Smith (Jarl), Kevin Adamson, Brydon Robertson, Dale Smith, Erik Moncrieff (in box top right).

Front row - left to right: Ross Smith, Ian Jarmson, Bobby Halcrow, Alma Stove, Leonard Christie.

Completed Galley at Naming Party

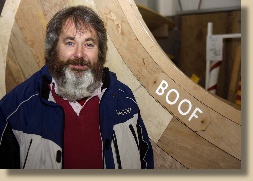

Boof attaching nameplate

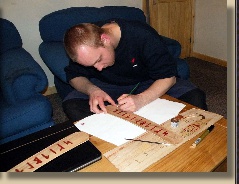

Scott Lobban Painting the nameplates

Bobby Halcrow painting

Ross Smith curving the

Galley Shields

Galley Shields

The curved galley shields

Janet Smith checking fangs

How the galley head will look

Taking shape with joke polystyrene head and temporary nameplate

Robert Halcrow painting the interior

Outer hull progressing

Inner hull being added

Fibreglassing and Sealing outer hull

Plank assembly before attaching to galley

Attaching planking

Constructing curved bow, stern and keel

Attaching base to keel

Attaching reference mould and planking

Galley on trailer ready for towing

Attaching Gunwale

Carved Galley Head attached

Completed Galley